If it has the required body, a thinner cake (5 mm) than can be handled by drum filters is feasible, allowing more difficult materials to be filtered. The strings return to the drum surface guided by two rollers, the cake separating from the strings as they pass over the rollers. String discharge RVDF system of endless strings or wires spaced about 13 mm (0.5 in) apart pass around the filter drum but are separated tangentially from the drum at the point of cake discharge, lifting the cake off as they leave contact with the drum. When acceptable, a sluice discharge makes cakes as thin as 1.5 to 2 mm (about gin) feasible. Thin cakes of difficult solids which may be slightly soluble are good applications. A special aligning device keeps the medium wrinkle-free and in proper line during its travel. Belt discharge RVDF carrying a fabric that is removed, passed over rollers, washed, and returned to the drum. In some cases the filter medium is held by circumferentially wound wires spaced 50 mm (2 in) apart, and a flexible scraper blade may rest lightly against the wire winding.Įxcellent for heavy solids and typical slurries are easy to filter. The scraper serves mainly as a deflector to direct the cake, dislodged by an air blowback, into the discharge chute, since actual contact with the medium would cause rapid wear. Scraper discharge RVDF medium is usually caulked into grooves in the drum grid, with cake removal facilitated by a scraper blade just prior to the re-submergence of the drum. The five basic discharge types are: SCRAPER DISCHARGE drum filters are ideally suited for filtering solids when cake washing is necessary when a uniform deposit of cake on the media is desired, or when the cake is difficult to discharge. Wide variations are possible in cycle time to ensure optimum cake formation, dewatering and washing on any application flow sheet. Vacuum filters are not as dependent on specific gravity differentials for the degree of clarity, nor are they subject to upset due to variation in the process.ĮIMCO-K.C.P drum filters provide high filtration rates and have excellent washing characteristics.

Vacuum filters allow a more complete separation of solids from liquids than other mechanical dewatering filters. This permit drum filters to be used in a variety of applications.

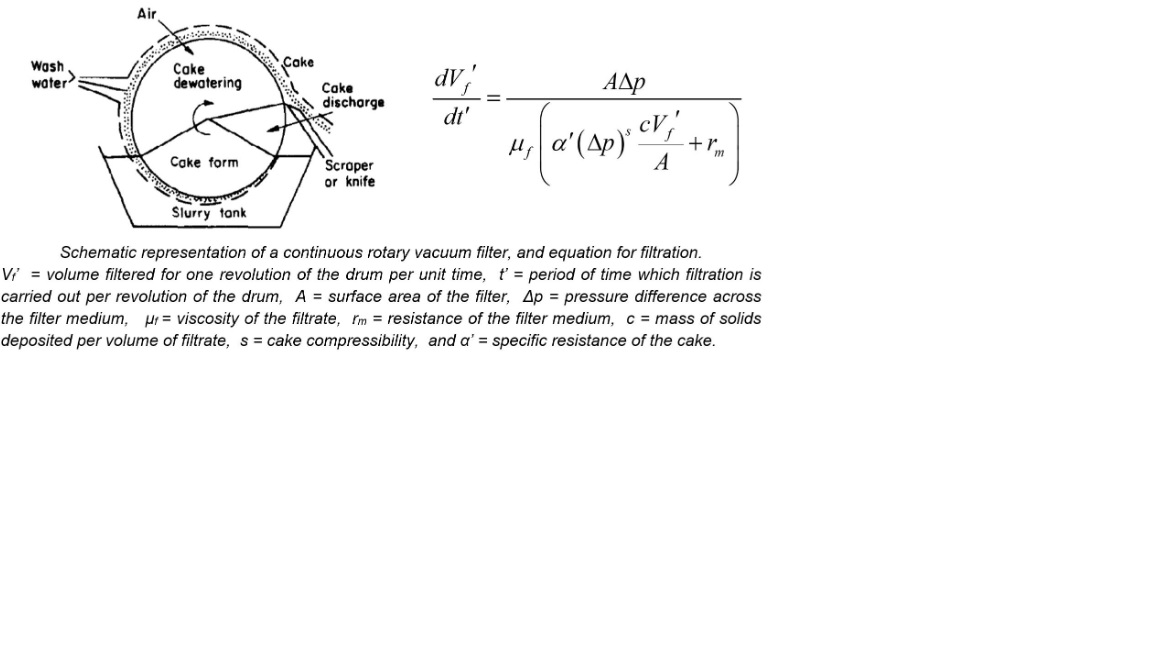

Continuous vacuum drum filters are designed to handle the broadest range of slurries of any filter.

0 kommentar(er)

0 kommentar(er)