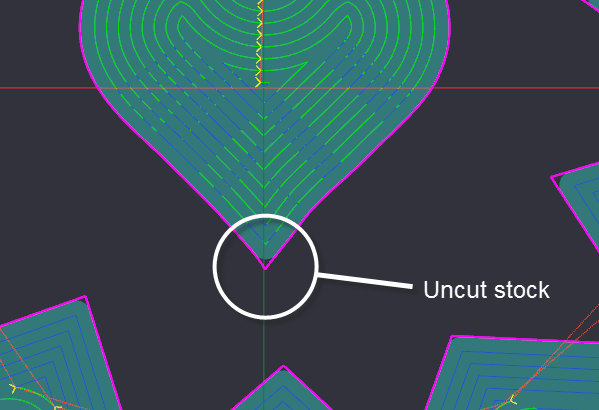

You might be wondering, why the faces are removed but the line and polygon geometry (on the top face) is kept. The faces are also removed to eliminated for the same reason. These are not needed as it will just double up on the geometry that we need. After the parts are exploded, any z geometry and back lines and polygons are removed. Second, all of the parts are exploded so we can remove the faces and geometry not needed in the CAM process. This will help in the CAM side of things. While the parts are arranged, the parts are oriented so that the counter bores and pockets are facing up. Additionally, the spacing of the parts by just a little more than the diameter of the bit can reduce the wear of the bit since during half of the passes, the end mill is only cutting very little material, since the material was already cut from the part next to it. The parts are spaced away from each other so that the end mill (bit/cutter) can fit between the pieces and that there can be a roughing pass and finishing pass. The parts are arranged in a way that the sheets are utilized as much as possible and the remainder is reduced for reuse.

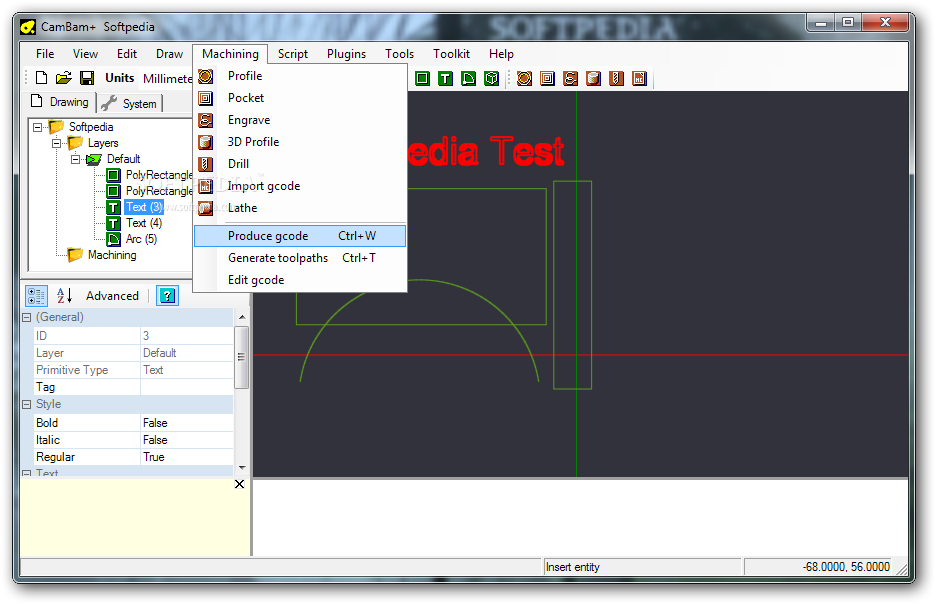

The point of this video is taking the 3 dimensional assembly and preparing it for use in a CAM program.įirst, the parts are all laid out on sheets just like they will be cut out on the CNC machine.

Since this is not a tutorial on using SketchUp, the drawing and designing portion of the video is sped up, but many of the design considerations can be seen. In this video, the assembly is being designed and drawing in SketchUp.

0 kommentar(er)

0 kommentar(er)